OEM Supplement Manufacture

Our experience in registering products ranging from product entry into the food act to supplement (MAL), traditional (MAL), cosmetics (NOT) and food products registrations.

Features

HEPA Filter Air Packing

Manufacturered under HEPA filter Air conditions, ensures lowest yeast and mold count.

< 55% Humidity

The air in products packed at our facility is below 55% relative humidity. Prolonging the life-span of powder products & caking issues.

HALAL

Our factory premise is Halal certified thus enabling registration of products for Jakim Halal

Scalable Output

We work closely with our customers and commit on delivery dates enable our customers to scale their business.

what we can pack

- Cannister

- Sachet

- Dripper Bottle

- Bottle

- Hot Fill

- Cold Fill

Examples of What We Can Pack.

Sachet Pack

Pouch Pack

Cannister

A Growth Partner for Manufacturing

Manufacturing

Awarded by the Malaysian Ministry of Science and Technology, recognizing Furley Bioextracts contributions and involvements in Biotechnology.

WHAT IS BIONEXUS STATUS?

BioNexus is a special status awarded to qualified international and Malaysian biotechnology companies. The status bestows fiscal incentives, grants and other guarantees to assist growth. This status is awarded to qualified companies undertaking value-added biotechnology and/or life sciences activies. Apart from the overall benefits and support, BioNexus companies are assured a list of privileges as stipulated in the BioNexus Bill of Guarantees.

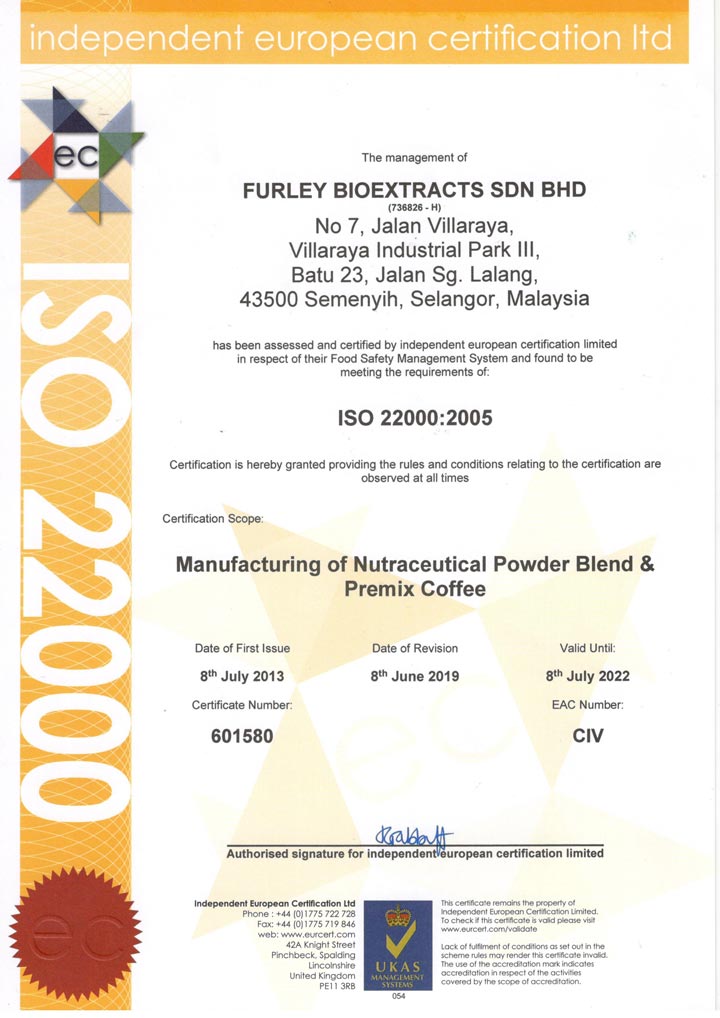

The selected certifying body for ISO22000 and HACCP enables products manufactured by FBIO to be exported to Europe.

Find out more about them here.

Additional certifying body for ISO22000 being Malaysian Standard.

The selected certifying body for ISO22000 by Malaysian Standards

The selected certifying body for ISO22000 by Malaysian Standards

Licence to operate a food premises in Malaysia.

The licence enables us to manufacture products which are not for consumption such as balms, liquids & cosmetic bases. These products require registration with the Malaysia Ministry of Health and have been classified as Traditional.

This certification allows us to manufacture unscheduled food supplements which can include supplements with claims.

This includes products with a hologram sticker which will encompass a unique serial number, known as the meditag. These are products which require registration with the Malaysian Ministry of Health.

The ISO 22000 family of International Standards addresses food safety management.

The consequences of unsafe food can be serious and ISO’s food safety management standards help organizations identify and control food safety hazards. As many of today’s food products repeatedly cross national boundaries, International Standards are needed to ensure the safety of the global food supply chain.

ISO22000 runs on-top of HACCP, further increasing traceability.

Establishment registration done for USA FDA enable Food and Cosmetics to be exported to USA.

Complementing external creams and balms for traditional and cosmetics are registered as a drug factory in the USA.

Undergoing Medical device warehousing and manufacturing as we expand for our customers needs.

The study of Rheology allows us to understand the behaviour of creams under parameters such as temperature. Having a thorough understanding of how the product performs in a day to day scenario.

While ensuring every batch manufactured has the same consistency and viscosity (thickness).

Making every lead and customer count.

In the competitive landscape we strive to give our customers the best impressions possible. With optimized taste and appearances.

Upon consumption unique tastes which are memorable and resonate your mission.

Not all powders are created equal.

Our 30+ years in manufacturing of powders we are able to deduce possible dry powder reactions which can result in product failure. Problems such as non-enzymatic brown and Maillard reactions can happen even with powders.

Extending further the smell, dispersion appearance and solubility of powders are clearly defined and optimised.

Using the latest scientific techniques such as LCMSMS we are able to deduce what are the compounds present in samples.

Testing for antioxidants and phenolic content values for standardization or for marketing information, ensures products made with us have a leading edge on the market.

We are able to accomplish this with our full time R&D team with PhDs, Masters in relevant fields of chemical analysis.

Ask us about creating live demonstrations for your product or customized testing suited for your product.

Sales & Marketing

The study of Rheology allows us to understand the behaviour of creams under parameters such as temperature. Having a thorough understanding of how the product performs in a day to day scenario.

While ensuring every batch manufactured has the same consistency and viscosity (thickness).

Making every lead and customer count.

In the competitive landscape we strive to give our customers the best impressions possible. With optimized taste and appearances.

Upon consumption unique tastes which are memorable and resonate your mission.

Not all powders are created equal.

Our 30+ years in manufacturing of powders we are able to deduce possible dry powder reactions which can result in product failure. Problems such as non-enzymatic brown and Maillard reactions can happen even with powders.

Extending further the smell, dispersion appearance and solubility of powders are clearly defined and optimised.

Using the latest scientific techniques such as LCMSMS we are able to deduce what are the compounds present in samples.

Testing for antioxidants and phenolic content values for standardization or for marketing information, ensures products made with us have a leading edge on the market.

We are able to accomplish this with our full time R&D team with PhDs, Masters in relevant fields of chemical analysis.

Ask us about creating live demonstrations for your product or customized testing suited for your product.

Sales & Marketing

The study of Rheology allows us to understand the behaviour of creams under parameters such as temperature. Having a thorough understanding of how the product performs in a day to day scenario.

While ensuring every batch manufactured has the same consistency and viscosity (thickness).

Making every lead and customer count.

In the competitive landscape we strive to give our customers the best impressions possible. With optimized taste and appearances.

Upon consumption unique tastes which are memorable and resonate your mission.

Not all powders are created equal.

Our 30+ years in manufacturing of powders we are able to deduce possible dry powder reactions which can result in product failure. Problems such as non-enzymatic brown and Maillard reactions can happen even with powders.

Extending further the smell, dispersion appearance and solubility of powders are clearly defined and optimised.

Using the latest scientific techniques such as LCMSMS we are able to deduce what are the compounds present in samples.

Testing for antioxidants and phenolic content values for standardization or for marketing information, ensures products made with us have a leading edge on the market.

We are able to accomplish this with our full time R&D team with PhDs, Masters in relevant fields of chemical analysis.

Ask us about creating live demonstrations for your product or customized testing suited for your product.